Air filters play a vital role in maintaining clean air quality and ensuring general health and safety. Air filters are designed to capture and remove airborne pollutants such as dust, pollen, smoke, and bacteria. They have been around for many years and have undergone numerous changes in design and technology. One can trace the history of air filtering back to ancient civilizations, where people used materials such as cloth, leaves, and animal skins to filter air. However, it wasn’t until the Industrial Revolution in the 19th century that air filters began to be used on a larger scale. Read More…

Duraflow Industries is the premier aftermarket and OEM supplier of various filtration products. We feature a complete line of filters for applications such as air scrubbers, absorption of thousands of organic compounds, drinking water filtration, and waste water abatement. Our just-in-time production techniques allow us to maintain production flexibility and meet fast turnaround times. From...

Clean Liquid Systems is a leading manufacturer of air and liquid filters. Our number one priority is to create the best filters that match the needs of our customers. We strive to have a fast turnaround while not reducing the quality of our products. Filtration is the only thing we do and ensure that we make our products right. We provide our customers with hundreds of years of experience and...

For more than 25 years, RoboVent's focus has been on the delivery of clean air and healthy environments in manufacturing facilities. This has earned us the leading position in the collection and filtering of airborne contaminants generated by metalworking and other industrial processes. We are passionate about providing clean air solutions to the industry, and this dedication to the cause brings...

Our world-class facilities set us apart from the competition. We work hard to make our customers happy with our air filters. We can provide what you need to keep your air clean in whatever industry you are in. Our goal is to exceed your expectations so you can focus on what you do best! Whether you need support in design, products, delivery, or support, we can supply it all!

At Tex-Air Filters, we pride ourselves on delivering exceptional air filter products that stand out in the industry. We understand the critical role air quality plays in maintaining healthy environments, and we are committed to providing top-tier filtration solutions. Our comprehensive range of filters is designed to meet the diverse needs of our customers, from residential spaces to large...

For over 29 years, Q-Air Environmental Controls has designed, serviced and installed dust collecting systems, including dust collectors, wet dust collectors and cyclone dust collectors. We also provide mist, smoke and fume collection systems. Contact us for quality dust collector products.

MCR inventories a large stock of Cleanroom Fan Powered and Ducted Air Filters. The Mac 10 FFU is known for being the quietest filter available and has been tested below 5O dBA with a rated flow of 90 FPM. Its modular design fits conveniently into 2`x4` to 2x2 T-Bar drop ceilings, and with a low profile of less than 13" it permits installation into tight ceiling spaces. Contact our company today!

More Air Filter Manufacturers

During the early 20th century, the use of air filters in heating and ventilation systems began, primarily in healthcare environments. The significant air pollution issues of the 1960s and 70s led to substantial progress in air filter technology. Today, air filters are crucial components of HVAC systems, employed across a wide array of applications.

Air Filter Materials

Air filters are primarily made from fibrous materials, with the selection of material varying according to the filter type and its specific use. Common materials include fiberglass, activated carbon, and synthetic polymer fibers, each chosen for their ability to tackle particular contaminants.

Fiberglass Fiberglass filters are widely used in both residential and commercial HVAC systems. They are efficient at capturing larger particles such as dust, pollen, and lint. These filters are economical and have minimal resistance to airflow, allowing the system to maintain optimal air circulation.

Activated Carbon Activated carbon filters are specifically designed to remove odors, volatile organic compounds (VOCs), and other gaseous pollutants. They operate by adsorbing contaminants onto the carbon’s extensive surface area. These filters are prevalent in air purifiers and industrial applications, where they significantly improve indoor air quality and safeguard workers from harmful substances.

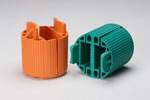

Synthetic Polymer Fibers

Filters made from synthetic polymer fibers, such as polypropylene or polyester, are typically used in environments that demand high levels of air cleanliness, like cleanrooms. These filters are designed to capture extremely small particles, including bacteria and viruses, and can be tailored to different filtration efficiencies based on the specific needs of the application.

Considerations for choosing the right filter material include cost, longevity, and the ease of installation and upkeep. Proper selection is essential to maintain air quality, optimize energy use, and ensure effective system operation.

Other Noteworthy Materials

Several materials beyond fiberglass, activated carbon, and synthetic polymer fibers are used in air filters. Aluminum mesh filters, for instance, are employed in commercial kitchens and industrial environments due to their durability and capability to capture larger particles like grease and oil mist. For residential HVAC systems, pleated paper filters offer a cost-effective solution, effectively trapping larger particles with moderate efficiency. Eco-friendly cellulose filters, derived from plant fibers, are utilized in both residential and commercial systems, providing good filtration. Silica gel serves as a desiccant, absorbing moisture to prevent mold growth and control humidity. Zeolite, a porous material, excels in adsorbing gases and odors, making it suitable for specialized applications. Carbon-impregnated filters merge activated carbon with other media to address both particulate matter and gaseous pollutants. Finally, filters coated with metal oxides such as titanium dioxide use UV light to catalyze the breakdown of harmful compounds.

How Are Air Filters Created

Manufacturers design air filters through various methods and materials to meet specific requirements and applications. The melt-blown process involves melting a polymer and directing it onto a surface, creating a mesh of fine fibers with a large surface area for effective particle removal. Electrostatic filters use a charge to attract and capture airborne particles, and can be constructed from synthetic or naturally charged fibers. The pleating technique folds the filter material to expand its surface area and boost particle retention. Air filter materials include fiberglass, activated carbon, synthetic polymers, and natural fibers like cotton or wool. Each material delivers unique filtration benefits, such as particle retention efficiency, gas absorption, and resilience. Manufacturers choose materials and methods based on the filter’s intended purpose and desired performance, tailoring filters to enhance indoor air quality.

Types of Air Filters

Air filters are available in a range of types, each meticulously designed to address specific needs.

Electrostatic Filters

Electrostatic filters harness an electrical charge to attract and capture airborne particles. This innovative technology enhances their ability to trap even the smallest particles, providing superior filtration compared to conventional filters.

HEPA Filters

High-Efficiency Particulate Air (HEPA) filters are distinguished by their ability to capture particles as diminutive as 0.3 microns. Their rigorous design ensures exceptional effectiveness in purifying the air, significantly reducing the presence of pollutants and allergens.

HVAC Filters

HVAC (Heating, Ventilation, and Air Conditioning) filters play a crucial role in enhancing both indoor air quality and energy efficiency within residential and commercial environments. These filters are integral to maintaining a clean and healthy atmosphere by trapping airborne particulates and contaminants before they can circulate throughout the space.

ULPA Filters

ULPA (Ultra-Low Particulate Air) filters are engineered to capture particles that are smaller than those managed by HEPA (High-Efficiency Particulate Air) filters. ULPA filters are essential in environments that demand the highest standards of cleanliness, such as cleanrooms, laboratories, and specialized manufacturing facilities, where even minute particulate matter could compromise the quality and safety of operations.

Inline Filters

Inline filters are employed in compressed air systems to safeguard the system’s components by removing various contaminants from the air stream. These filters ensure the purity and efficiency of the compressed air, protecting equipment from damage and enhancing overall system performance.

Exhaust Filters

Exhaust filters are utilized in engines and industrial equipment to purify exhaust emissions. By capturing pollutants and particulate matter from exhaust gases, these filters contribute to environmental protection and compliance with regulatory standards, reducing the impact of exhaust fumes on air quality.

Foam Filters

Foam filters are frequently used in water filtration applications, including aquariums and other aquatic environments. These filters effectively capture debris and particulates from the water, ensuring a cleaner and healthier habitat for aquatic life.

Air Compressor Filters

Air compressor filters are specifically designed to remove moisture, oil, and other contaminants from the compressed air generated by air compressors. By maintaining the integrity of the compressed air, these filters help prevent equipment malfunction and extend the lifespan of the system.

Limitations of Air Filters

While air filters provide significant benefits, it’s crucial to recognize their limitations. One key limitation is potential airflow reduction. As air flows through a filter, resistance can restrict flow, affecting system efficiency and potentially increasing energy consumption. Additionally, air filters require regular maintenance and replacement; over time, filters can become clogged with particles, diminishing their effectiveness and further impeding airflow. Neglecting maintenance can lead to reduced filtration efficiency and compromised air quality. Furthermore, standard filters are often ineffective at removing gases, volatile organic compounds (VOCs), and chemical odors. Addressing these pollutants may necessitate specialized filters or additional air purification technologies. Understanding these limitations aids in setting realistic expectations and making informed decisions about air filter use and overall air quality management. Regular maintenance and considering environmental needs can help mitigate these limitations and ensure optimal performance.

Benefits of Air Filters

Air filters significantly improve air quality and foster a healthy environment in diverse settings. In homes, HVAC systems incorporate air filters to eliminate pollutants and allergens, enhancing air purity and mitigating respiratory concerns. Commercial establishments, such as offices, retail outlets, and dining venues, benefit from air filters by creating a more comfortable and inviting atmosphere for employees and patrons. Industrial operations use advanced air filters to safeguard workers from harmful particles, gases, and fumes generated during production processes.

In healthcare facilities, air filters play a key role in controlling airborne contaminants and ensuring sterile conditions in operating rooms and cleanrooms. The aviation and aerospace sectors rely on air filters to maintain optimal cabin air quality for passengers and crew members. Overall, air filters are essential in protecting health and ensuring clean environments across residential, commercial, industrial, healthcare, and transportation domains.

Applications of Air Filters

Air filters play a crucial role in enhancing air quality and maintaining a healthy environment across a range of settings. In residential homes, HVAC systems use these filters to trap pollutants and allergens, leading to cleaner air and reduced respiratory risks. Commercial spaces, such as offices, retail areas, and restaurants, benefit from improved indoor air quality, which creates a more comfortable atmosphere for employees and customers.

Specialized air filters in industrial facilities protect workers from harmful particles, gases, and fumes produced during manufacturing processes. In healthcare settings, these filters are essential for minimizing airborne pathogens and ensuring sterile conditions in operating rooms and cleanrooms. The aviation and aerospace industries rely on air filters to maintain cabin air quality, supporting the health of passengers and crew. Across residential, commercial, industrial, healthcare, and transportation sectors, air filters are indispensable in promoting cleaner environments and safeguarding human health.

Choosing the Correct Air Filter

Selecting the right air filter involves several key considerations. First, identify the types of pollutants or particles to be addressed, such as dust, allergens, odors, or chemicals. This will help narrow down the filter options. Next, determine the necessary filtration efficiency based on the level of particle removal required. High-efficiency filters, like HEPA or ULPA, may be needed for fine particles. Assess the system’s airflow capacity to ensure the filter does not excessively impede airflow, considering factors like size, pressure drop, and airflow rate. Also, review the filter’s lifespan and maintenance needs, as some filters require more frequent replacements or cleaning. Lastly, consulting HVAC experts or air filtration specialists can provide valuable guidance in choosing the appropriate filter. Careful consideration of these factors will ensure the selection of an air filter that meets the specific needs of the application.

Choosing the Correct Air Filter Supplier

To ensure the best results when purchasing air filters, start by comparing suppliers in our directory. Each supplier has a profile that details their expertise and services, along with a contact form for requesting more information or quotes. Quickly understand each company’s specialization using our website preview tool, and then simplify the process of requesting quotes by using our RFQ form to reach out to multiple suppliers.

Air Filters

Air Filters Liquid Filters

Liquid Filters Filtering Systems

Filtering Systems Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services